Crafted Shield for a

Lasting Marine Legacy

What can be coated with Forticoat?

-

Rusty port

-

Vessel

-

oil and gas drilling

-

Storage and Cargo Containers

-

Splint

-

Speedboat and emergency boat

Forticoat related material

Fluorine

Paint 750

Paint 880

Water proof paint

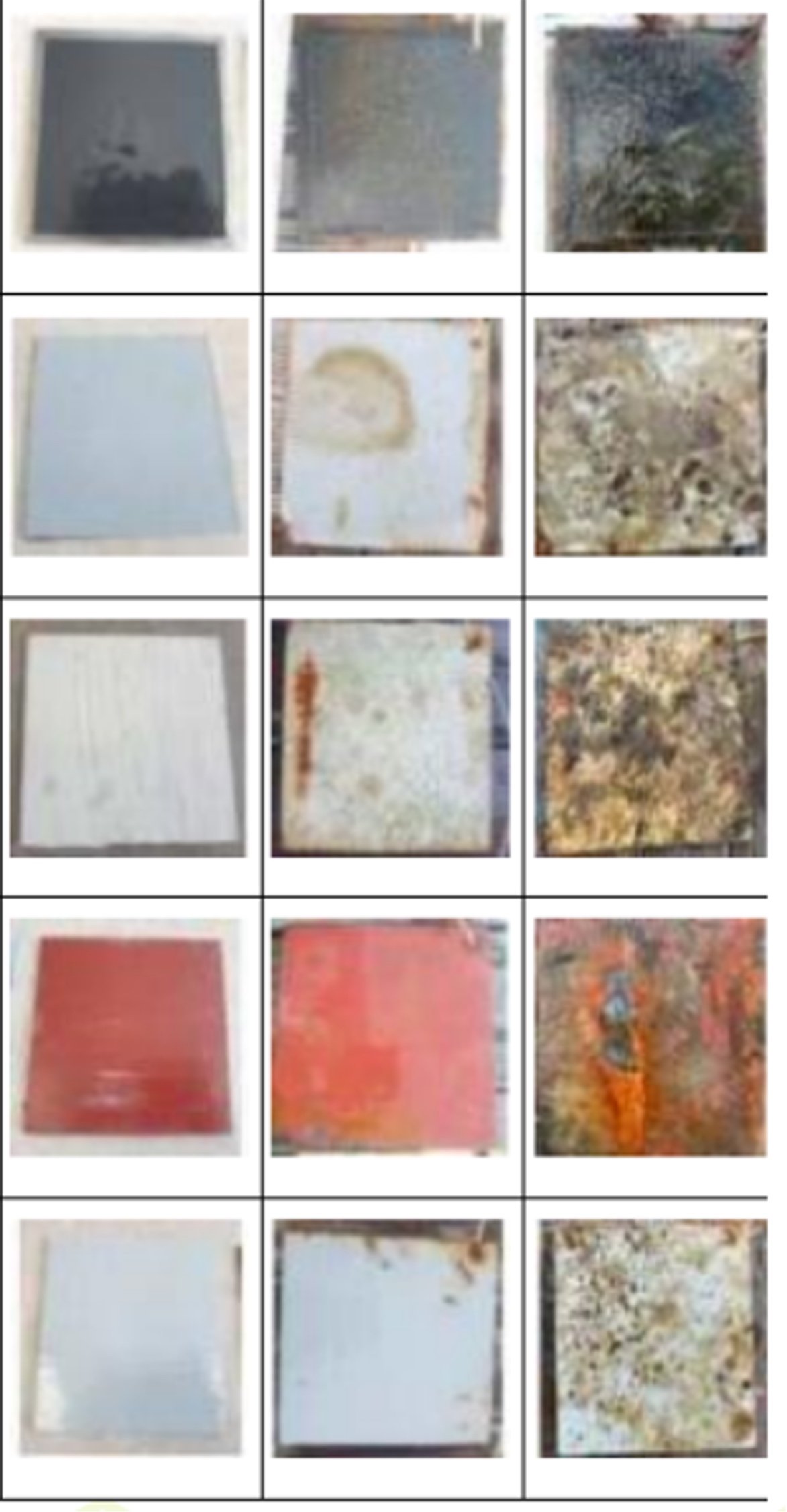

Before Testing3 months6 monthsMonitoring surface conditions by anti-fouling sample for 6 months

Son, J.H., Kang, M.B., Jung, K.K. and Han, W.B., 2024. Development of Anti-Fouling Film Using Polyurea for Offshore Wind Turbine Substructure. Journal of Wind Energy, 15(1), pp.82-90.

The experiment monitored fouling and biofouling on samples over six months. Five products were tested: Forticoat-like membrane, Fluoro membrane, Antifouling Paint 750, Antifouling Paint 880, and Waterproof Paint, all applied to 10x10 cm steel plates. A control group of known waterproof and antifouling products was also included. Fluoro membrane offers excellent weather, fouling, and heat resistance, while Antifouling Paint 750 and 880 are widely used for ship exteriors. Waterproof Paint, with nanopore structures, is designed for building waterproofing and corrosion protection. At an average seawater temperature of 19.2°C and a depth of 1-4 m, slight moss appeared after three months, and significant fouling occurred on all samples by six months.

Comparison of bio-fouling occurrence areaIt all begins with an idea.

The bar chart presents a comparative analysis of biofouling coverage across each sample tested in real marine conditions. Six months post-immersion, specimens were cleaned and evaluated to measure biofouling area on each sample.

Of the five samples tested, the biofouling area on the Forticoat-like membrane sample was 17.24%, while the fluorine membrane showed 65.36% coverage.

Upon cleaning, biofouling residues were successfully removed from all samples; however, only the antifouling paint 750 exhibited damage, with peeling on the painted surface.

In conclusion, Forticoat displayed the best overall performance, with minimal biofouling coverage and excellent surface durability after cleaning, making it an optimal choice for biofouling resistance.